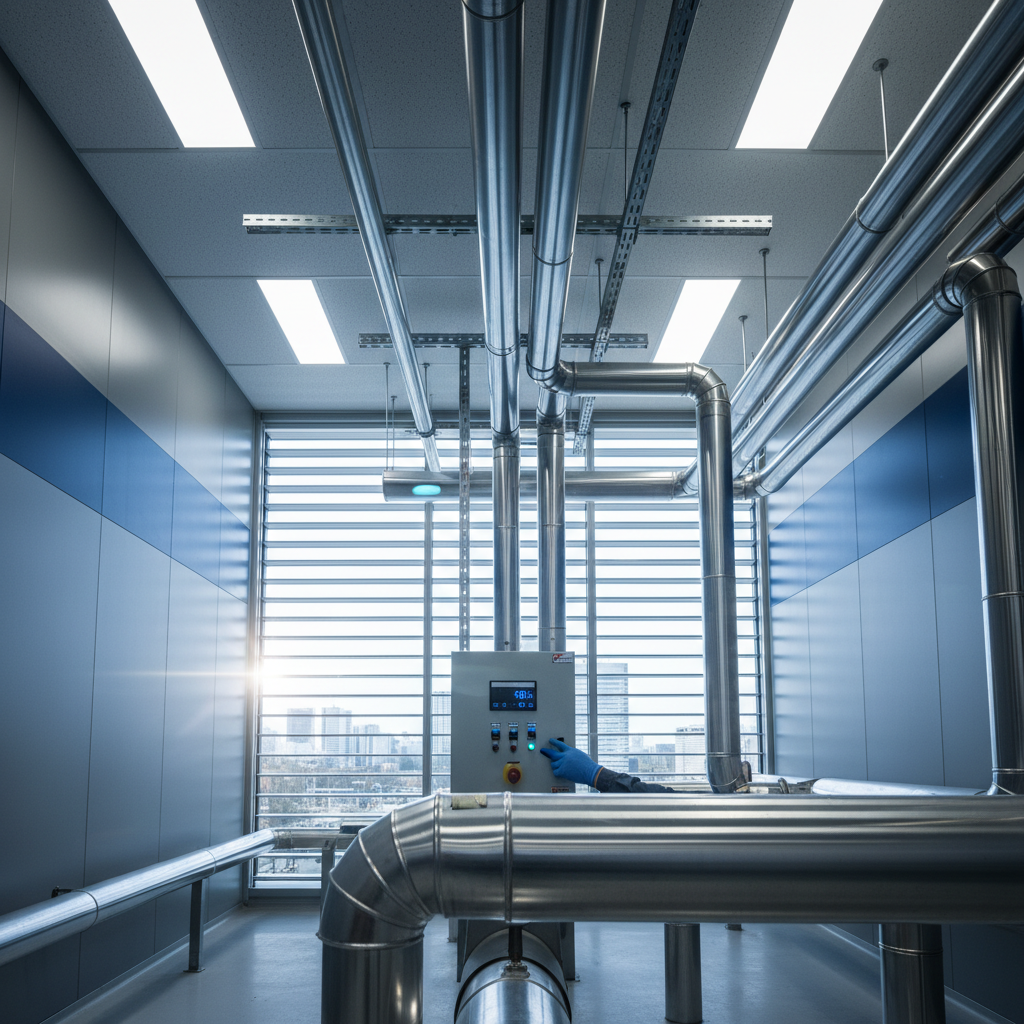

A sudden HVAC failure in a bustling London office block during peak summer doesn't just spike temperatures—it triggers £5,000+ emergency call-outs, lost productivity at 20% per affected floor, and potential non-compliance fines under the London Plan's net-zero rules. I've seen facility managers watch their quarterly budgets evaporate in a single afternoon because they treated MEP as an afterthought rather than the commercial lifeline it actually is.

When ventilation and heating systems are neglected, the resulting downtime can cripple business operations and lead to costly emergency repairs. Proactive management of these systems is essential for avoiding budget overruns and maintaining compliance.

MEP = Mechanical, Electrical, Plumbing - the three core building systems that keep commercial properties operational, compliant, and profitable in London's demanding regulatory environment.

MEP encompasses three critical building systems: Mechanical (HVAC, ventilation, heating), Electrical (power distribution, lighting, controls), and Plumbing (water supply, drainage, public health systems). In London specifically, these systems face stricter Part L Building Regulations demanding 31% carbon reduction compared to the UK average, driven by rising energy costs that have increased 15% year-on-year.

The key difference between MEP and traditional M&E lies in integration. While M&E often silos mechanical and electrical, london mep services coordinate all three disciplines from day one, preventing the costly retrofits I see when plumbing is treated as an afterthought—typically adding 10-15% to project costs.

| Aspect | MEP Approach | Traditional M&E |

|---|---|---|

| System Integration | All three disciplines coordinated | Mechanical & electrical focus |

| Design Clashes | 40% reduction via early coordination | Higher rework rates |

| Compliance Ease | Holistic regulatory approach | Fragmented compliance checks |

| Sustainability Focus | Integrated net-zero planning | Retrofitted green solutions |

The London Plan mandates net-zero readiness by 2030, with MEP systems handling 40% of building emissions. This isn't just regulatory compliance—it's commercial survival. Poor MEP design translates directly to 25% higher energy bills, while properly engineered systems deliver 15-20% savings through efficient technologies like air-to-water heat pumps and integrated building management systems.

Consider a high-rise office in Westminster facing electrical overload during peak demand. Without proper MEP load calculations, you're looking at potential blackouts, emergency generator costs, and tenant compensation claims. We calculate electrical loads using diversity factors to ensure total demand stays below 80% capacity—preventing the cascade failures that cost thousands in lost business continuity. Our london mep approach integrates BIM modeling for 3D clash detection within two weeks of the design phase, catching problems before they reach the construction site.

The hiring process follows six critical steps: 1) Define your scope (new build vs refurbishment), 2) Verify ISO 9001/14001/45001 accreditations, 3) Review portfolios for comparable projects, 4) Request detailed PPM quotes, 5) Demand a comprehensive site survey within 48 hours, 6) Secure turnkey delivery with defined handover criteria. Don't accept vague timelines—demand specifics on compliance certificate delivery.

Implementation follows a structured timeline: Concept phase (1-2 weeks for load modeling), Design development (4 weeks including BIM coordination), Installation (6-12 weeks depending on complexity), and Handover with compliance certificates delivered within 24 hours. The key is continuity—ensure the same engineer handles your site throughout to spot building-specific quirks that reduce repeat visits by 30%.

During implementation, schedule quarterly PPM visits and inspect filters every three months. Replace any filter showing more than 5mm buildup to maintain 12% efficiency gains. For fit-out projects, digital traceable certificates aren't optional—they're your legal protection against compliance failures that can trigger significant fines under current London regulations. For more insights on urgent maintenance issues, read about commercial building maintenance problems you need to fix ASAP.

London's ULEZ expansion drives electrification demand, making air-to-water heat pumps with COP 4.0+ efficiency the new standard. At M&E Maintenance Solutions, we internally test these systems before client rollout, ensuring real-world performance matches manufacturer claims. Installation typically completes in 2-3 days and cuts gas consumption by 70%.

Five proven sustainable upgrades delivering measurable ROI:

| System Type | Annual Cost | Carbon Emissions | Install Time | ROI Timeframe |

|---|---|---|---|---|

| Gas Boiler | £3,500 | High | 3-5 days | N/A (legacy) |

| Air-to-Water Heat Pump | £1,800 | 70% lower | 2-3 days | 4-6 years |

| Solar PV + Heat Pump | £1,200 | 85% lower | 5-7 days | 5-7 years |

For a deeper look at recent MEP installations, see how our team completed a Coventry University chiller pipework install.

Coordination clashes between ductwork and pipework plague 60% of London projects. BIM modeling eliminates these conflicts before installation, reducing rework by 50%. The most expensive mistake I see is treating MEP disciplines separately—a blocked drain in Balham cost one client £15,000 in emergency repairs because plumbing wasn't integrated with mechanical ventilation design.

Non-compliance with Part L regulations hits facility managers hardest during building assessments. Poor ventilation control leads to CO2 levels exceeding 1000ppm, triggering mandatory system upgrades. Our london mep approach prevents these failures through six-monthly PPM audits that catch issues before they become legal problems.

| Problem | Symptom | Root Cause | Solution |

|---|---|---|---|

| System Clashes | Installation delays | Poor coordination | BIM modeling from design phase |

| Energy Drift | Rising utility bills | Inefficient controls | Quarterly filter checks + tuning |

| Compliance Failures | Regulatory notices | Skipped maintenance | SFG20-compliant PPM schedule |

| Emergency Breakdowns | System failures | Reactive approach | Proactive monitoring + spares |

For more on identifying HVAC issues before they escalate, check out these common signs you need commercial HVAC repair.

Selection criteria center on four non-negotiables: proven experience (minimum 10 years), full accreditation suite (ISO 9001/14001/45001 plus Constructionline), diverse portfolio demonstrating multi-discipline capability, and innovation through internal testing protocols. Avoid firms that subcontract core disciplines—you need single-point accountability for complex london mep projects.

M&E Maintenance Solutions stands apart through founder-led expertise spanning 25+ years, from apprentice-level technical mastery to strategic asset management. Our internal testing protocol vets heat pumps and solar systems on our own facilities before client deployment, ensuring real-world performance data. We maintain 99% uptime across London estates through 24/7 response capability and continuity—the same engineer handles your site, learning its specific quirks and requirements.

Skipping PPM isn't cost savings—it's a £50 filter turning into a £5,000 compressor failure when summer demand peaks. At M&E Maintenance Solutions, we ensure SFG20 compliance and 24/7 uptime for your London assets because reactive maintenance is the most expensive strategy you can choose. Planned intervention prevents the cascade failures that shut down business operations.

Contact M&E Maintenance Solutions today for a comprehensive MEP audit that protects your assets, cuts operational costs, and maintains London compliance. We're big enough to handle complex commercial demands, small enough to care about the details that keep your building running. Call 0121 380 5630 or email for immediate response—because breakdowns don't work 9 to 5, and neither do we.

The London Plan's 2030 net-zero mandate will reshape MEP requirements fundamentally. Heat networks and district cooling systems are becoming mandatory for developments over 1,000m², while the ban on gas boilers in new builds from 2025 accelerates heat pump adoption. Smart building integration through IoT sensors and AI-driven optimization will become standard, not optional.

Electrification infrastructure demands careful load planning now. The National Grid's capacity constraints in Central London mean new electrical connections face 18-month delays. Forward-thinking facility managers are securing electrical capacity today, even for future phases. Solar PV paired with battery storage offers grid independence—crucial when London's energy costs rise 20% annually. For further technical guidance, see UCL's Design Guidance for MEP.

Successful london mep implementation requires three fundamentals: integrated design from day one, compliance-first approach to avoid regulatory penalties, and proactive maintenance to prevent costly failures. The firms that excel combine technical depth with commercial understanding—they speak both boiler room and boardroom fluently.

M&E Maintenance Solutions delivers this rare combination through founder-led engineering expertise and 24/7 commercial support. Our track record across London's diverse building stock—from Victorian conversions to modern high-rises—proves our adaptability. We don't just install systems; we optimize building performance for the long term, ensuring your investment delivers maximum ROI while meeting evolving regulations.

Start with a comprehensive building audit focusing on energy performance and compliance gaps. Document current systems, identify inefficiencies, and prioritize upgrades based on payback periods. For existing buildings, heat pump feasibility studies and electrical capacity assessments are essential first steps. You might also be interested in signs you need to call a professional plumber for your property.

Contact M&E Maintenance Solutions for a no-obligation site survey that identifies immediate opportunities and long-term strategies. Our engineering team provides detailed reports within 48 hours, complete with cost projections and compliance roadmaps. Call 0121 380 5630 today—because in London's competitive property market, efficient MEP systems aren't just about compliance, they're about competitive advantage.

London MEP integrates Mechanical, Electrical, and Plumbing disciplines from the outset, unlike traditional M&E which often treats these systems separately. This coordination prevents costly retrofits and design clashes, typically saving 10-15% on project costs and ensuring smoother compliance with London's stringent regulations.

Poor MEP design leads to inefficient systems that drive up energy consumption, increasing operational costs by as much as 15% annually. It also risks non-compliance with the London Plan's net-zero carbon targets, exposing building owners to significant fines and reputational damage.

HVAC failures in London offices can trigger emergency repair costs exceeding £5,000 and reduce productivity by 20% per affected floor. Proactive MEP management through Planned Preventative Maintenance (PPM) helps prevent unexpected breakdowns, controls costs, and maintains business continuity.

Innovations like heat pumps, solar PV integration, and smart building controls enhance energy efficiency and reduce carbon footprints. These technologies align with London’s sustainability targets while lowering running costs and improving occupant comfort.